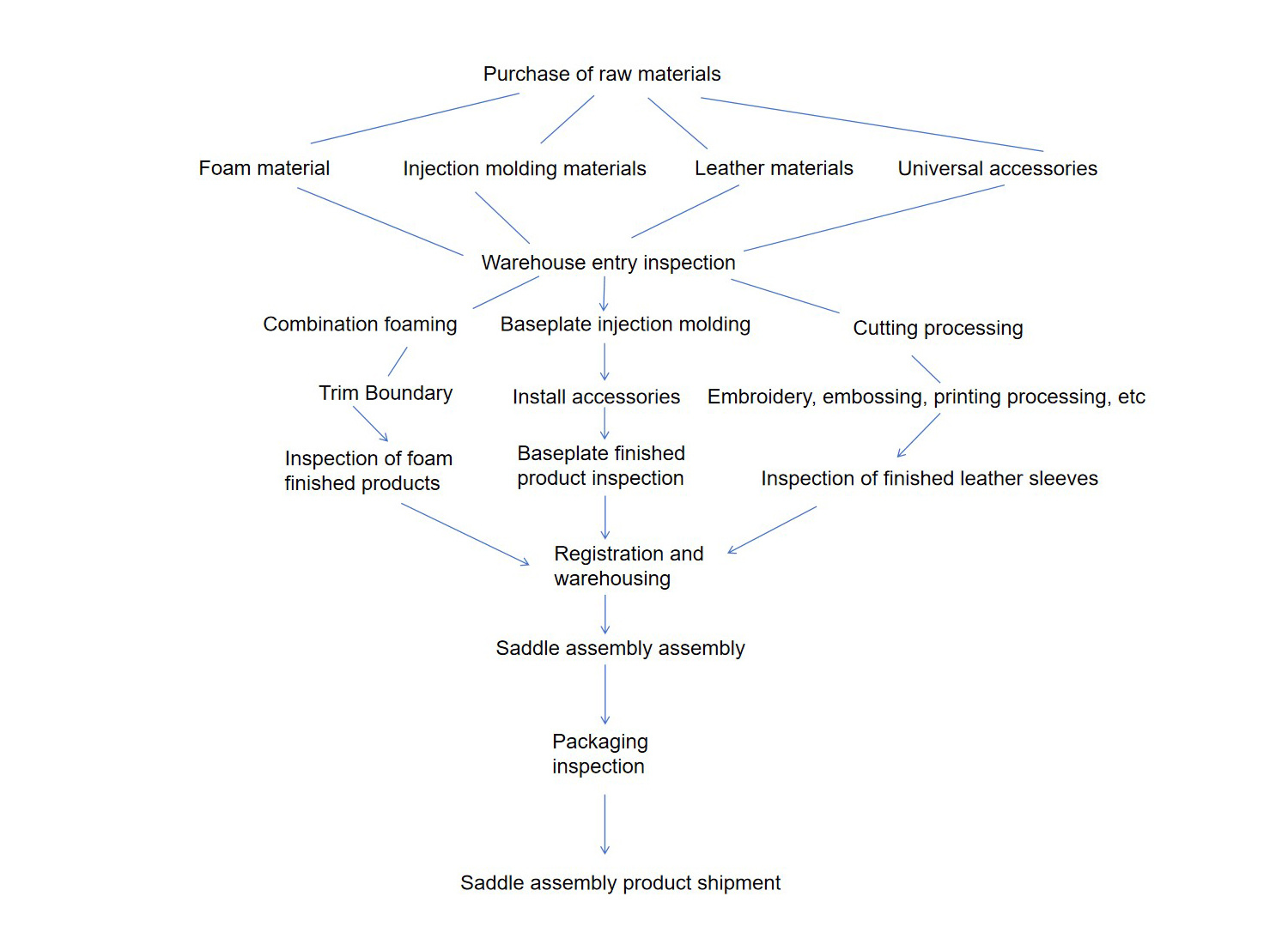

Saddle production process flowchart

Quality monitoring of raw materials

Raw Material MSDS Manual

Supplier Material Inspection Report

Quality monitoring of raw materials is a critical aspect of ensuring the overall quality of the final product. To effectively monitor the quality of raw materials,We establish clear quality standards

·Conduct regular inspections

·Using multiple methods to test raw materials

·Maintain proper storage conditions

·Supplier evaluation

·Document and track data

·Implement corrective actions

Establish effective monitoring measures from R&D to production

We have established a unique and effective production management system based on customer requirements and our own needs, effectively supervising all aspects of research and development, production, and sales. Our goal is to establish a sound quality system and improve efficiency at all stages. Through data-driven decision-making, we have established a culture of continuous improvement and are concerned about the impact of the production process on the environment, enabling us to continue to develop.

In-house testing equipment

The company continues to improve its internal quality inspection equipment and system. The existing testing equipment can complete multiple inspections of incoming materials and production lines:

Leather part

Some physical property tests, leather color fastness, leather abrasion resistance, leather aging resistance, etc.;

Foam part

Foam density and hardness test, sponge rebound test, 75% indentation hardness test, etc.

Third-party inspection report

At present, 100% of foam products can pass the REACH and ROHS related testing requirements. Flame retardant foam that meets the requirements of BS5852 can be produced according to the requirements.

The baseplate can meet the ROHS and flame retardant related requirements according to the requirements.

Leather can meet the requirements of ROHS, flame retardancy, mite resistance, and UV resistance for 800 hours without fading.